Fig.1 Triaxial Quartz Accelerometer.

In various industries, such as aerospace, automotive, and robotics, there is a need to precisely measure the inclination angle of objects. Triaxial accelerometers play a crucial role in fulfilling this requirement. This article delves into the fundamentals of triaxial accelerometers to gain a deeper understanding of their functionality and applications.

Whether it's in the inertial measurement systems of space vehicles, the inclination measurement of vehicles and ships, the balance attitude detection of robots, or the limb posture detection in medical applications, these sensors utilize MEMS technology to measure inclination angles effectively. Notably, they offer advantages such as small size, light weight, affordability, and minimal interference with the mechanical mechanisms of the objects being measured.

1.Types of Acceleration Sensors

There are three main types of acceleration sensors: piezoelectric, capacitive and thermal. Classified by the number of input axes, there are single-axis, dual-axis and triple-axis accelerometers. Each of these has their own advantages. Take the technical principle of capacitive triaxial accelerometer as an example.

Capacitive accelerometers can sense motion conditions such as acceleration or vibration in different directions. It is mainly a movable mechanism designed using the mechanical properties of silicon. The mechanism mainly includes two sets of silicon comb teeth, when one is fixed, and the other is moved immediately; the former is equivalent to a fixed electrode, and the latter is a movable electrode. When the movable comb teeth are displaced, there will be a change in capacitance proportional to the displacement.

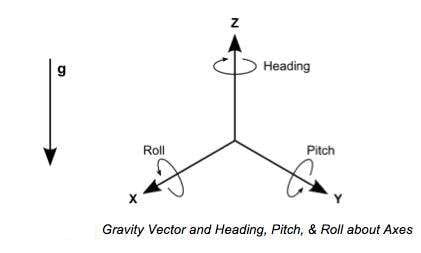

Triaxial accelerometers are actually 3 distinct accelerometers mounted in the orthogonal X, Y, and Z directions. Integrated packaging brings all 3 accelerometers into a single cube with a single cable harness and overall 3–to–1 reduction in cabling.

Fig.1 Triaxial Quartz Accelerometer.

2.How does a triaxial accelerometer work?

Most of the three-axis accelerometers use piezoresistive, piezoelectric and capacitive working principles. The resulting acceleration is proportional to the changes in resistance, voltage and capacitance, and is collected through corresponding amplification and filter circuits. This is based on the same principle as an ordinary accelerometer, so in a certain technology three single-axis can become a three-axis.

Since the three-axis accelerometer is also based on the principle of gravity, the three-axis accelerometer can realize the double-axis plus and minus 90 degrees or the acceleration generated by the double-axis three-axis proportional to the change of resistance, voltage and capacitance, and is collected through the corresponding amplification and filter circuit.

Triaxial accelerometers have measurement bandwidths (up to 15 kHz) for condition monitoring of critical machine operations. It works on the basis of acceleration. Acceleration is a space vector. On the one hand, to accurately understand the motion state of an object, the components on its three coordinate axes must be measured; the acceleration signal must be detected.

Fig.2 three axis accelerometer principle

3.Application of Triaxial Accelerometer

Automotive: In the automotive industry, triaxial accelerometers are integrated into vehicles for stability control systems, rollover detection, crash sensing, and impact detection. They play a crucial role in enhancing vehicle safety by detecting sudden changes in acceleration and triggering appropriate safety measures such as airbag deployment.

Industrial Monitoring: Triaxial accelerometer sensors offer data insights enhancing efficiency and utilization of industrial machinery. Embedded 3-axis accelerometers excel in monitoring machine health, necessitating attributes like wide bandwidth, compact size, low power consumption, and consistent performance.

Robotics: Triaxial accelerometers are essential components in robotic systems for balance and motion control. They enable robots to detect changes in acceleration and orientation, allowing for precise movement and navigation in dynamic environments.

Structural Health Monitoring: Biaxial accelerometers typically meet requirements adequately for many sensor applications. Yet, specific contexts demand three-axis accelerometers, notably in data mining equipment, valuable asset monitoring, collision detection, and measuring vibrations in large-scale structures such as buildings and wind turbines. They measure vibrations and dynamic loads, providing valuable data for assessing structural stability and detecting potential defects or damage.

Fig.3 Triaxial Accelerometer integrated in manufacturing environments

Fig.3 Triaxial Accelerometer integrated in manufacturing environments

4.Summary

The versatility and precision of triaxial accelerometers make them essential tools across a wide range of industries, driving innovation, enhancing safety, and enabling new possibilities in fields ranging from aerospace and automotive to robotics and healthcare.

The ER-3QA-02D triaxial accelerometer stands out for its remarkable precision, comprising three A15 acceleration sensors, a 24-bit high-precision A/D converter, a 16-bit ultra-low power consumption single-chip microcomputer, and a robust mechanical structure. Noteworthy features of the ER-3QA-02D include digital output, high precision installation error, temperature compensation, and low power consumption. These attributes render it highly adaptable across a diverse spectrum of industries.